More than a supplier

Rynkeby Maskinfabrik takes pride in being more than just your supplier of machining services. We are your partner, whether you are a customer or subcontractor.

We firmly believe that together we make each other stronger and that it is through joint development projects and sparring that we can come up with the best possible solution for you as a customer.

For almost 130 years, this attitude has characterized Rynkeby Maskinfabrik. We continue to live these values in everyday life and make sure they are a natural part of our culture by also strengthening collaboration and relationships between employees.

You probably know him. The good friend you can always count on, where the sky is the limit and there is understanding and mutual respect. You can ask him for advice because he is an expert in his field and knows his stuff. He acquires the latest technology, but never compromises on the old virtues and craftsmanship – he believes heritage is of great importance.

That’s how we want to be at Rynkeby Maskinfabrik. It’s been with us from the very beginning. Back when apprentices and employees lived at the factory and became part of the family, customers became close business partners, and the concept of ‘family business’ extended far beyond the ties of blood. Then, as now, our business, markets and customers have been characterized by constant change from the technological development. This places great demands on keeping a sharp eye on the horizon, being adaptable and embracing the technologies of the future.

However, no matter how fast we move into the future, we still think like ‘the good friend’. We don’t forget our heritage. We remain rooted in the virtues that have shaped us: craftsmanship, integrity and quality, and an unwavering belief that relationships and people make the difference. So even though work and home are now separate, employees are still at the heart of our business. Opportunities arise through their technical knowledge, commitment and interest in our customers.

Just as a friendship doesn’t exist without two parties, we are nothing without our customers. The collaboration and trust when we gain insight into their business makes us want to develop and do even better. This means that we don’t just create machine parts, but deliver complete solutions that embrace both high-complexity special tasks as well as the more common ones. Enabling our customers to focus on their core business. That’s exactly what we feel passionate about.

TIMELINE

With a passion for traditional and solid craftsmanship, machine builder Jacob Rasmussen founded Rynkeby Maskinfabrik in 1895. Today, machines have become more advanced, efficient and precise, but Jacob Rasmussen’s passion for good, solid craftsmanship is still our focus.

Our affiliation with Funen and not least Rynkeby is strong. Today, our office is located on the site where Jacob Rasmussen lived from 1876-1895. Right here in Rynkeby he started his business adventure and set up his first machine shop. This is also where Rynkeby Maskinfabrik has grown over time into a healthy business with around 45 employees and 6,000 square meters under roof, from where supply machining to more than 50 different industries.

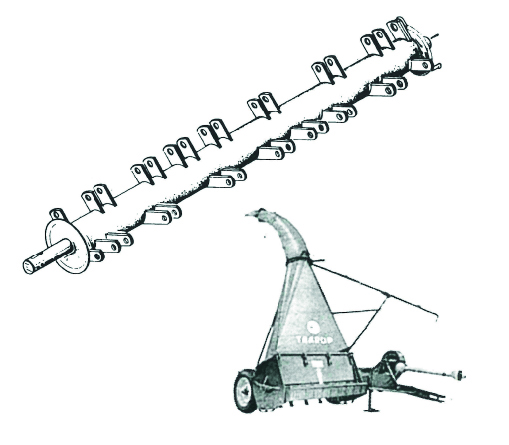

Jacob Rasmussen founds the factory, which manufactures agricultural machinery, including threshing machines. The factory has both its own machine shop and carpentry workshop and the machines are pulled via belt drive, pulled by a horse-drawn carriage and later its own windmill.

The next generation, sons Rasmus and Hans-Jørgen take over the company, which now changes name to Brdr. Rasmussen Maskinfabrik.

The apprentices are given room and board with the family, and Rasmus’ wife Inger Rasmussen comes up with the idea of using fallen apples from the garden for apple juice that the apprentices among other things benefit from. This is the beginning of Rynkeby Mosteri, founded in the family’s utility room. Over the years, Rasmus and Hans-Jørgen have produced small machines for must production.

Rasmus and Inger’s sons, Tyge and Uffe, join the company and the business continues to develop.

At the end of the 1950s, actual series production began and until the mid-1980s, Taarup agricultural factory in Kerteminde is one of the largest customers – the company employs over 80 people. The processes are in addition to machining, Welding and painting.

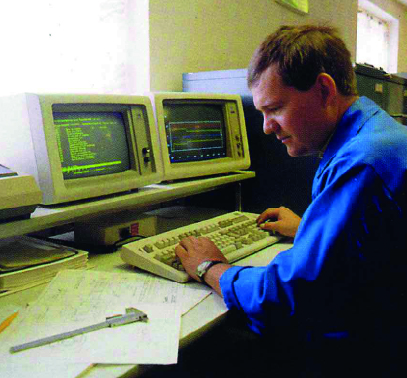

A limited liability company is established and the first CNC machines and computers become part of everyday life. Throughout the 1980s, more and more customers appear, including Man B&W, Volvo, Micro Matic, Grundfos, The Bridge, Svendborg Brakes and Vestas. The focus is mass production.

Production continues to develop at a rapid pace, and throughout the 1990s investments are made in CNC machining centers, CNC cylindrical grinding and measuring machines .

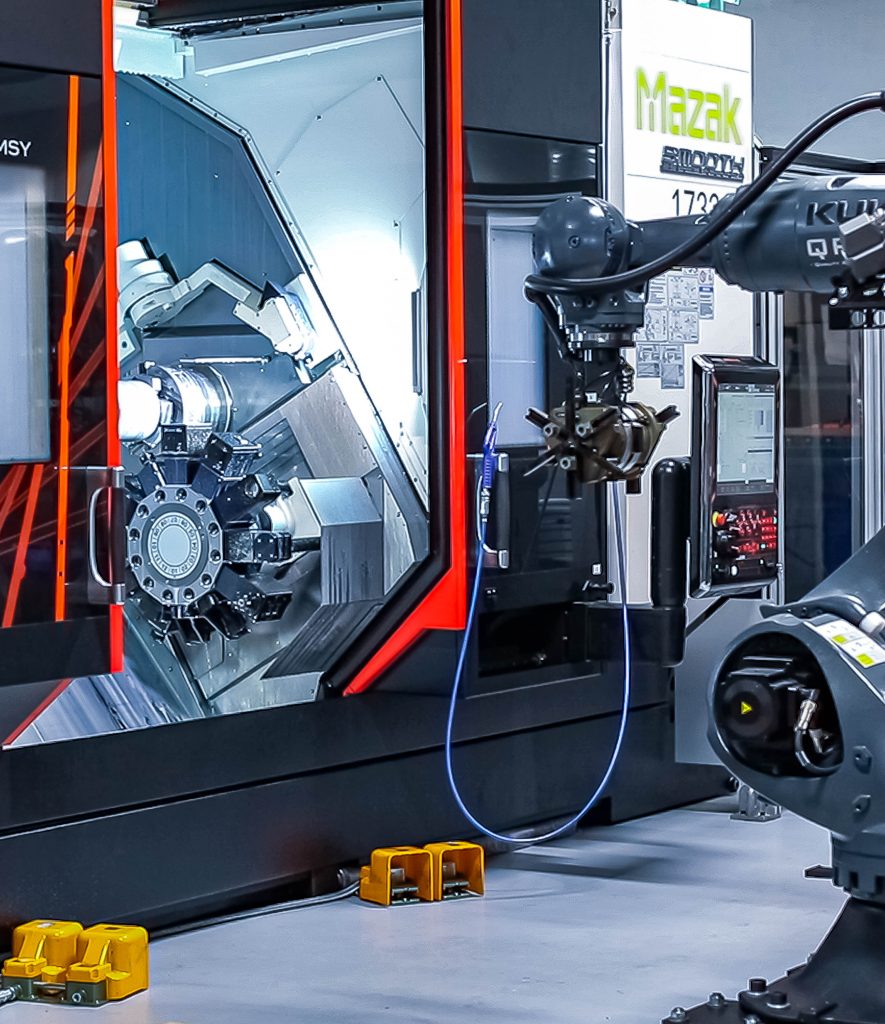

Over the years, more and more production in the industry has moved to Eastern Europe and Asia, which is also a reality at Rynkeby Maskinfabrik. Therefore, a new strategy is launched, focusing on skill-intensive machining, with high demands on quality, small series and short delivery times. Machinery is continuously replaced and employees are trained in the new requirements. In 2007 we implemented the first Multitasking machine, which was followed by a large number of new machines in the following years.

The first robot cell is implemented and the company now has, among other things, 3 multitasking machines, in addition to a wide range of lathes, horizontal machining centers and cylindrical grinding machines.

Massive investments are being made in the latest technology to keep up with customer needs, and preparations for a FMS system for the machining centers are initiated. Buildings upgraded and working environment improved with new hybrid heating system and ventilation system while saving the environment +140 tons of CO2 annually.

Rynkebyvej 238

5350 Rynkeby